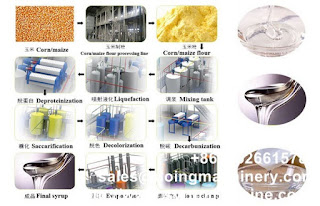

How to produce high fructose corn syrup ?

Before answer the question how to produce high fructose corn syrup , let's learn about the high fructose corn syrup. High fructose corn syrup also known as confectioner's glucose, is a syrup made from the hydrolysis of starch. Glucose also is called starch sugar. Maize (corn) is commonly used as the source of the starch to produce glucose, then adopt isomerism process change glucose into fructose, in which case the syrup is called "corn syrup", but glucose syrup is also can be produced from cassava, potato , wheat , rice and other starch source material. Chat Online Next is our high fructose corn syrup production process introduction: - Mixing slurry: Put the corn starch and water into the mixing tank, then put in enzyme, keep on particular standard temperature, waiting for some time , then transport to next work section. - Injector liquefaction: The mixed corn powder/ rice pwoder milk is sent to buffer tank then liquefied by jet cooker with t...