Cassava starch production process

The cassava starch manufacturing process is a physical separation process which means that the starch in the cassava raw material is separated from impurities of starch slurry thorough a series of processing procedure. And the production process is divided into transportation, cleaning, washing, crushing, screening, concentration and refining, dehydrating, drying and packaging.

Cassava starch manufacturing process

Here are the detail introduction of the cassava starch manufacturing process

1. Raw material choosing and transportation process:

Choosing: The raw materials of cassava starch include fresh cassava and dried cassava chips, which are the main substances for production. In cassava starch manufacturing process, it is required that the raw cassava must be fresh. It will be better to purchase, transport and process the fresh raw material on the same day. The chosen raw cassava should be no damage, not mildewed, not degraded, and free from insects.

Transportation: The cassava is transported from the storage yard to the cleaning machine by using a conveyor, and it is required to ensure the sufficient supply of the raw materials of the process. In the process of transportation, it is necessary to prevent the inclusion of iron, nails, stones, wood and other debris. If debris is found, it should be picked up in time.

Cassava washing machine

2. Cleaning and washing process:

The cleaning and washing are the first step for cassava starch manufacturing process. The cleanness of raw material has an important influence on the quality of the end cassava starch. Therefore attention should be paid for this process. The dry sieve and paddle washing machine are the widely used machine for this process. The cassava raw material is rolled and transported along with the dry sieve to remove the sand, stone, weed and other impurities. Then they are transported into paddle washing machine, and is sprayed, washed, bathed and cleaned with water as a medium.

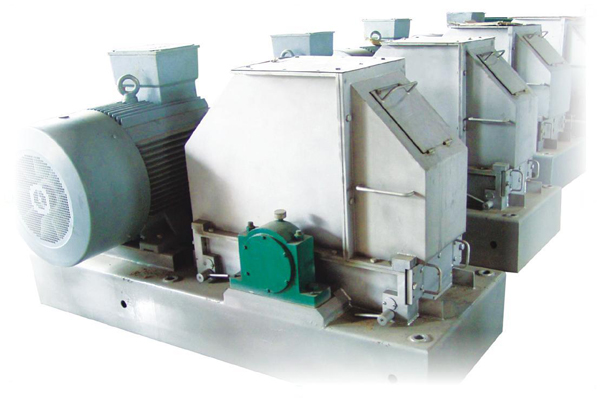

3. Crushing process:

The role of crushing is to destroy the structure of cassava, so that tiny starch granules can be disintegrated and separated from the roots of cassava. In cassava starch manufacturing process, the widely used crushing machine is rasper. The machine relies on high-speed operation to disintegrate cassava so that the starch granules are continuously separated. And the disintegrated cassava is processed into starch slurry by using water as a medium.

Cassava crushing machine

4. Screening process:

The crushed starch slurry need to be screened to separate the starch milk from the fibers. At present, the centrifuge sieve and fine fiber sieve are widely used for separating in cassava starch manufacturing process. The two machines are used together, that is, the centrifuge sieve is firstly used to separate fiber from starch by high speed centrifugal force, while the fine fiber sieve is used to further separate fine fiber out of starch slurry by taking use of low speed centrifugal sieve. And the combination of the two machine can achieve a better screening effect.

5. Concentration and refining process

The function of this process is to remove insoluble protein and residual soluble protein and other impurities from the starch slurry, thereby achieving the purpose of washing, refining and concentrating the starch milk. At present, the hydrocyclone station is commonly used for washing, refining and concentrating in cassava starch manufacturing process. According to the different specific gravity of water, starch and yellow pulp protein, this machine can effectively remove the impurities.

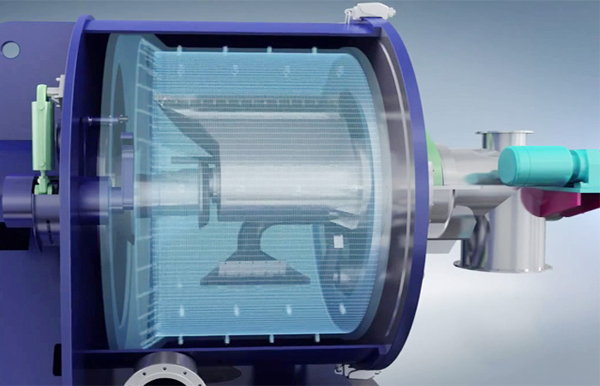

Peeler centrifuge

6. Dehydrating process

After the concentration and refining process, the concentrated starch milk still contains a large amount of water, and thus must be dehydrated to facilitate drying. At present, the peeler centrifuge is widely used for dewatering in cassava starch manufacturing process. It is required that the moisture content of the wet starch after dehydration is less than 38%.

7. Drying and packing process

The wet starch dehydrated by peeler centrifuge is transferred to flash dryer for drying. The steam pressure is controlled at 0.8 MPa. It is required to after the drying process, the moisture content of the finished starch is about 13.5%. Then the starch is packed for storage. And this process requires a sufficient number of bags, a firm package, and timely storage.

Cassava starch drying machine

Cassava starch drying machine

Doing Company is engaged in the cassava processing business, we can provide you with high quality cassava starch processing machine used in the cassava starch manufacturing process.

Email: sales@doingmachinery.com

Website:https://www.cassavastarchmachine.com

Comments

Post a Comment