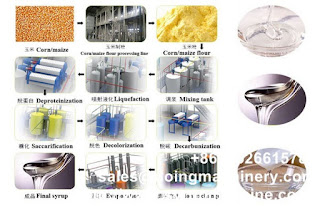

Glucose syrup production process for how to make glucose syrup ?

We are a professional glucose syrup production machine manufacturer and supplier, can make the turn key project for glucose syrup production plant for you, also can install the maltose syrup production plant , and the high fructose corn syrup factory installation. Following is the glucose syrup production process detail introduction: 1. Raw material checking and feeding: The raw material(starch) requests its water content less than 14%, no mildew, after checking, send them to conveyor. 2. Glucose syrup production mixing and liquefaction process: Mixing the starch with water, adjust the concentration to 18Be, PH value 5.6-6.0. After the α-enzyme which is high temperature resistance adding, conveying to jet liquefier with steam heating up to 100-108℃ to be liquefied. 3. Protein filtration: The liquid hydrolysis qualified dextrin solution (DE value about 20) is sent to the plate frame filter press machine to filter protein, the separated proteins can be washed, dried and c...